Recommended Taps for Roscamat Tapping Arms

Share

Roscamat’s rugged tapping arms make tapping easy for machining operators. Their lightweight, compact size and ancillary tapping tables allow for easy set up and relocation for reaming, countersinking, fastening, Helicoil® insertion and small diameter drilling jobs. Plus, with electric and pneumatic options, Roscamat’s robust materials and construction provide a lifetime of use.

Our tapping experts recommend specific taps for use with the Roscamat tapping arm.

Types of Thread Taps

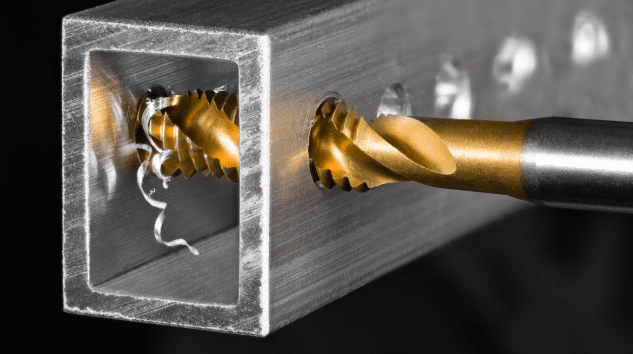

In the machining world, tapping refers to forming internal threaded holes in a workpiece to accept corresponding threaded fasteners or attachments. These are typically created using a cutting tool called a tap.

Although hand taps, also known as straight flute taps, are commonly used, we do not recommend using them with the Roscamat tapping arm. This is because the chips collect in the flutes, causing thread quality problems.

Spiral point, spiral flute and forming taps are ideal for tapping arms and CNC applications.

Cut CNC Milling Time with Automated Deburring and Roscamat Tapping Arms

What to consider when choosing a tap for your application:

- Type of hole

- Material compatibility and hardness

- Hole size

- Thread quality requirements

These factors are critical in tap selection, so knowing each tap’s differences, advantages and constraints is important to make the optimal decision.

Three types of production taps we recommend for use with Roscamat:

Spiral Point Taps (Gun Taps)

These taps have a spiral cut with an angled point and relief grooves. The angled point provides superior cutting performance and helps shoot the chips forward in through holes.

Spiral Flute Taps

These taps have an open spiral cut and a blunt tip. They pull chips up and out of the hole. These are ideal for blind hole tapping.

Form Taps (Roll Taps)

These taps don’t cut threads; they form them by pushing metal out of the way and compressing the threads into position. This means there are no chips to remove. As a result, the taps are less likely to break and the threads are stronger.

How to select the right production tap for your application

Choosing the right cutting tap depends on a specific application’s hole features, material and quality needs. The general applications for hole features are:

- Through Holes - tapping the thread hole all the way through the part

- Blind Holes - tapping the threaded hole to a specific depth and does not exit the piece

- Interrupted Holes – tapping a hole that intersects with another feature within the material

Whether you need to tap a through hole, a blind hole or interrupted hole determines the types of taps to consider.

Watch Roscamat in action: Brad’s new video - 100RPM speed module being used to drill, countersink, and ream.

Recommended Taps for Through Holes

Spiral Point Taps: This is ideal for tapping through holes because the tap pushes the chips forward during the tapping process. The chips go through the hole, and the thread is clean when you back the tap out. This is the least expensive thread tap you might consider using for production tapping.

Recommended Taps for Blind Holes and Interrupted Holes

Spiral Flute Taps: The holes from these taps will be fairly clean because you’re pulling the chips up and out of the hole as you tap. These taps are always preferable when you have a blind hole and can also be used for an interrupted hole because the spiral helps restart the threading past the open feature.

Recommended for Through Holes or Blind Holes in Soft Materials

Forming Taps. These are best used in materials that flow, such as steel, stainless steel or aluminum (up to a hardness of 36 HRC or 340 BHN). A forming tap doesn’t generate any chips so they can be used for through or blind holes. However, they are a little more expensive and generate a little more torque, which is not a problem for Roscamat tapping arms. Note that forming taps require different starting hole sizes.

Whether you use a cutting or forming tap, Roscamat tapping arms can increase productivity as well as improve employee ergonomics and safety.

Learn More: 6 Things to Know about Roscamat Tapping Arms

Need more help deciding what type of tap to use on your Roscamat tapping arm? Contact our team for expert advice for setting up your tapping arm.